About us Snap

Founded in 2011, SNAP Automation operates in the integration of industrial automation systems. The company performs the interconnection of equipment, thus developing intelligence so that communication between the machines takes place at the right time.

SNAP serves large car assemblers and machine manufacturers, as well as the industry in general, producing white goods (stoves, refrigerators, electric saws, lawn mowers, among other household appliances). Because, the investment in automation makes the processes more agile, profitable and competitive.

Snap Skills

Production of modular and integral software;

Specialized, experienced and trained team;

Guarantee of a quality standard;

Expertise in application engineering;

Development options for the requested project;

Speed in the execution of the work;

Production of technology through robotics;

Best Practices;

Efficiency in the desired solution.

Why automate processes in a company

Speed

Greater agility and productivity in product manufacturing.

Efficiency of production

Greater volume of products and agility between ordering the product and the start of production.

Security

Elimination of many risks in the operation of machines, with the use of sensors.

Higher added value to employee work

More valuation of the professionals’ dressing and less physical activities.

Process of feedbacks (return) of reliable production controls

Accurate data of what is running.

Quality

Greater guarantee of quality standard in the manufacturing process and consequently in the product produced.

Manpower

Quality of life for employees, less physical effort on the part of the team.

Lowest Cost

Hiring a reduced number of people and consequently lower costs with social obligations.

Increased market competitiveness

Product customization faster.

Sustainability

Better thought-out processes, with reduced waste of materials and inputs, which results in less waste generation, less electricity consumption and less air pollution.

Snap ready for industry 4.0

In the sense that companies need their processes increasingly automated and interconnected, SNAP has prepared itself over its years in the market to enter what is called industry 4.0. Thus, industry 4.0 is a recent industry concept that encompasses the main technological innovations in the fields of automation, control and information technology, applied to manufacturing processes. As a result, production processes tend to become more and more efficient, autonomous and cost-effective. This means a new period in the context of the great industrial revolutions.

Therefore, automation is responsible for taking the workload off the “back” of the operator. In other words, it runs processes that can be up to 100% automated, with employees working in machine and process management and no longer in the manual operation of equipment.

Who does Snap serve?

Industry

Process engineering and maintenance engineering; management areas (MES, ERP); and business management (consulting)

Machine Manufacturer

Process engineering and maintenance engineering; management areas (MES, ERP); and business management (consulting)

Special Equipment Manufacturer

Process engineering and maintenance engineering; management areas (MES, ERP); and business management (consulting)

Control Pack

Process engineering and maintenance engineering; management areas (MES, ERP); and business management (consulting)

Products / services that Snap offers

Software

Development of intelligence and logic for controllers, robotics, supervision and management.

Manufacture of switchboards

Panel assembly

Assembly lines

Several special machines that work by developing a linear process.

Retrofit machines

Renovation of a finished machine, which involves redoing the software, in addition to making electrical and/or mechanical changes to meet the functionality.

Distribution of automation equipment

Sale or supply of components for industrial automation.

Consulting in automation

Analysis of the situation or production process, with the aim of improving the production system.

Electrical Projects and Panels

Development of electrical connections for machines, assembly lines or robotic cells and layout of components for control panels.

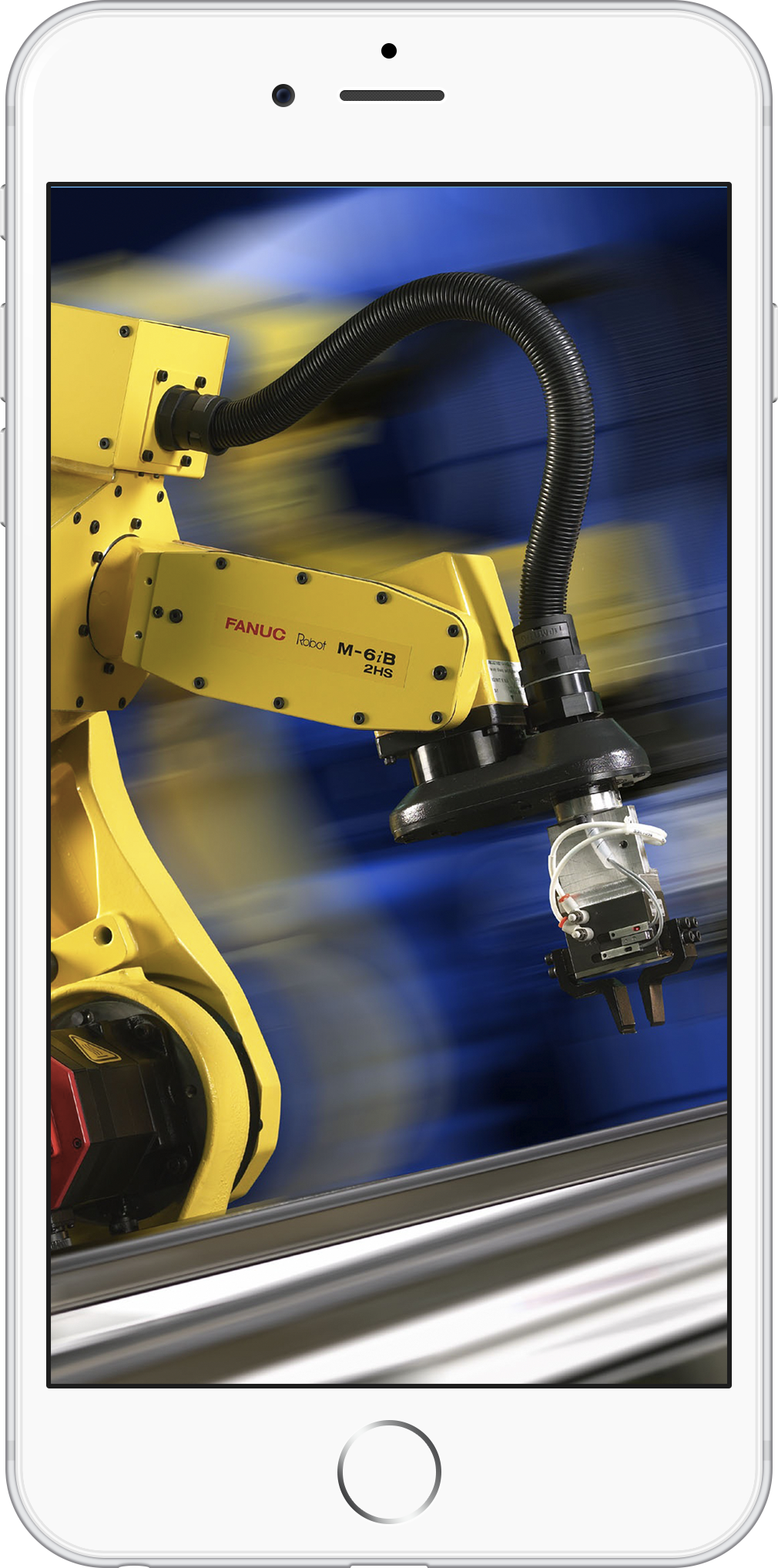

Robotic cells

Determined space where it contains different machines and a robot that performs a specific function (product handling, palletizing, welding and painting).

Electrical installations

Panel supply, motor and valve activation and sensor installation.

NR12 Security

Adaptation of the equipment so that it complies with the mandatory NR12 Safety requirements for machines.

Development of automated special machines for productive processes

Manufacture of this type of specific equipment.

Software Development and LabView™ Test Benches

Manufacture of this type of specific equipment.

Snap is a Specialist in LabView™

Snap Automation uses the development environmentLabVIEW da National Instruments for control, data acquisition (DAQ) and test bench applications. Our LabVIEW development team has been working on solutions that run on a variety of hardware and operating systems, including Windows PCs and Systems Boarded as NI Real-Time controllers and NI FPGA platforms.

We help our customers with:

- LabVIEW Application Development

- UI design

- Control project (PID, Fuzzy Logic)

- Data management (files, TDMS, database)

- Reports and Data Display

- Deployment and startup

- Integration with hardware

- API and SDK development

- Machine Learning